Letina Intech: Global Benchmark in Custom-Engineered Stainless Steel Solutions

Engineering the Future of Global Industry

In a landscape moving away from “one-size-fits-all” equipment, Letina Intech provides the strategic advantage of custom engineering. From our 30,000 m² facility in Croatia, we deliver technically complex, stainless steel assets to over 60 countries.

Custom Engineering Focus: We eliminate spatial and process constraints found in standard catalog equipment.

Global Compliance: Our vessels meet rigorous ASME U, PED 2014/68/EU, and ISO standards.

Vertical Integration: In-house control over 3D laser processing and final polishing ensures “Build-to-Print” accuracy.

Our Certificates

ISO 9001

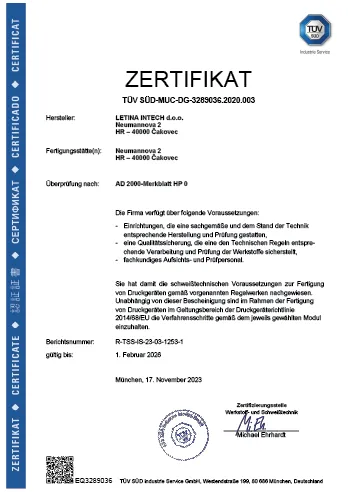

PED 2014/ 68/EU

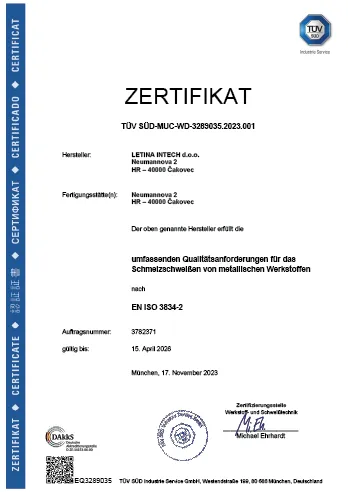

EN ISO 3834-2

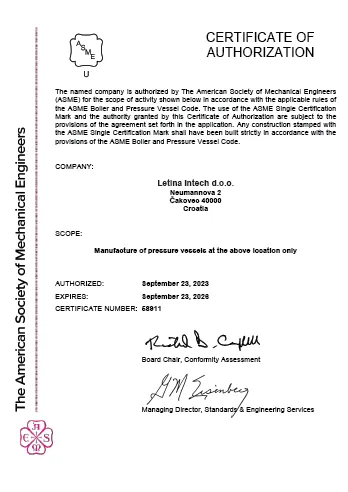

ASME U

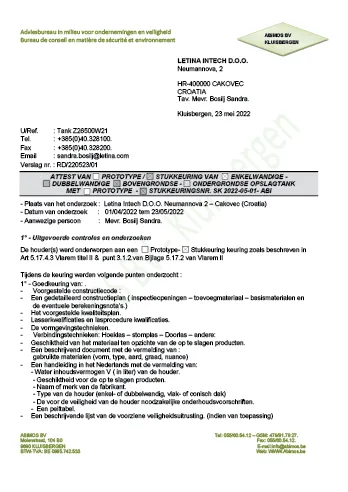

VLAREM II

Our Certificates

ISO 9001

Quality management system

PED 2014/ 68/EU

Pressure Equipment Directive

EN ISO 3834-2

Quality requirements for fusion welding of metallic materials

ASME U

Boiler and Pressure Vessel Code

VLAREM II

Flemish Regulations on Environmental Permitting

Solutions Specialized by Industry

Wine & Enology

Precision fermentation tools including "Winematic" agitators and space-saving square tanks.

Brewing & Process

High-performance CCTs and Brite Beer Tanks designed for sterile, repeatable results.

Food & Beverage

Specialized mixing systems for high-viscosity products like condiments and dairy.

Industrial Storage

Large-scale silos reaching capacities of 280,000+ liters.

Transport

ATP-regulated tanker semi-trailers for safe, hygienic food transport.

The Nexus of Technology and Precision

Our manufacturing superiority is underpinned by a park of over 300 machines, featuring Trumpf 3D laser systems.

-

Advanced Metrology: We utilize Hexagon 3D measuring arms to verify data points against original drawings.

-

Mirror Finishes: Guaranteed surface roughness (Ra ≤ 0.4 μm) for strict hygiene applications.

-

Heavy-Scale Fabrication: Facilities with 19-meter ceilings and 15-ton cranes allow for the assembly of ultra-large process modules.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor in

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor in

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor in

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor in

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor in

Nam commodo suscipit

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo