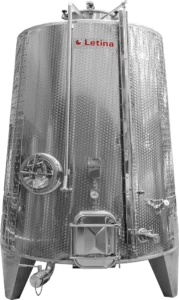

Wine Tanks and Equipment

Custom Stainless Steel Solutions for Global Wine Production

From boutique estates to global industrial cellars, we provide the custom stainless steel tools required to protect the integrity of your fruit and the artistry of your wine.

From the estate cellars of France and Germany to the high-throughput facilities of the USA, Letina Intech is the strategic partner for producers who refuse to compromise. We don’t just manufacture tanks; we engineer enological assets that protect the aromatic profile and structural integrity of your wine.

60 Years of Heritage: Founded in 1963, we combine decades of European winemaking tradition with 21st-century industrial scale.

Precision Surface Integrity: We guarantee mirror-polished interior finishes (Ra ≤ 0.4 μm / BA IIId) to eliminate bacterial “dead zones” and optimize CIP efficiency.

Certified Compliance: All pressure-rated vessels are fully compliant with ASME U and PED 2014/68/EU standards.

ISO 9001

Quality management system

PED 2014/ 68/EU

Pressure Equipment Directive

EN ISO 3834-2

Quality requirements for fusion welding of metallic materials

ASME U

Boiler and Pressure Vessel Code

VLAREM II

Flemish Regulations on Environmental Permitting

GMP

Compliance for stainless steel surfaces in contact with food

Winery-Specific Stainless Steel Tanks

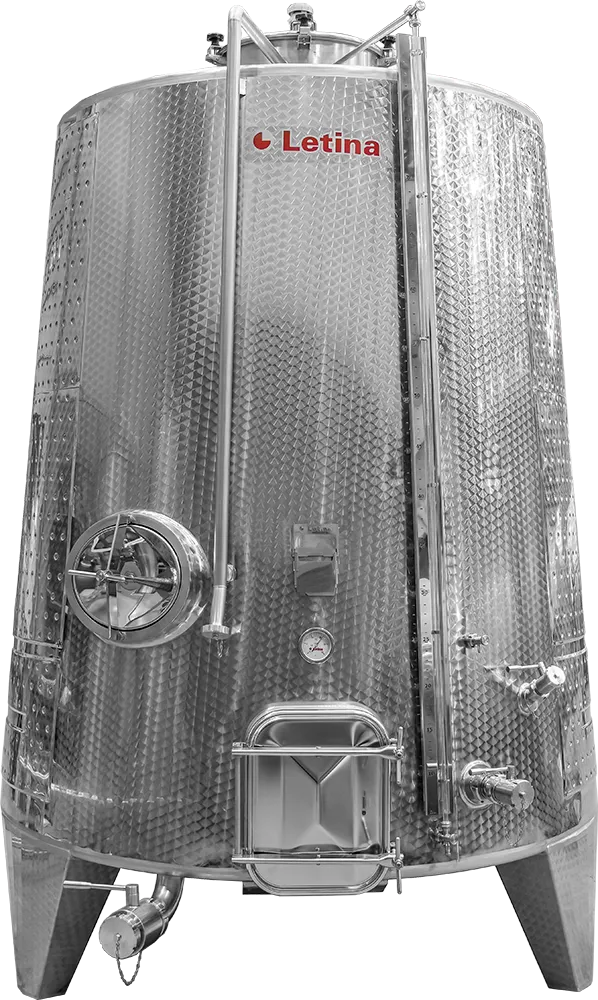

Pump-Over Fermenter

[VIK] Pump-Over Fermenter

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

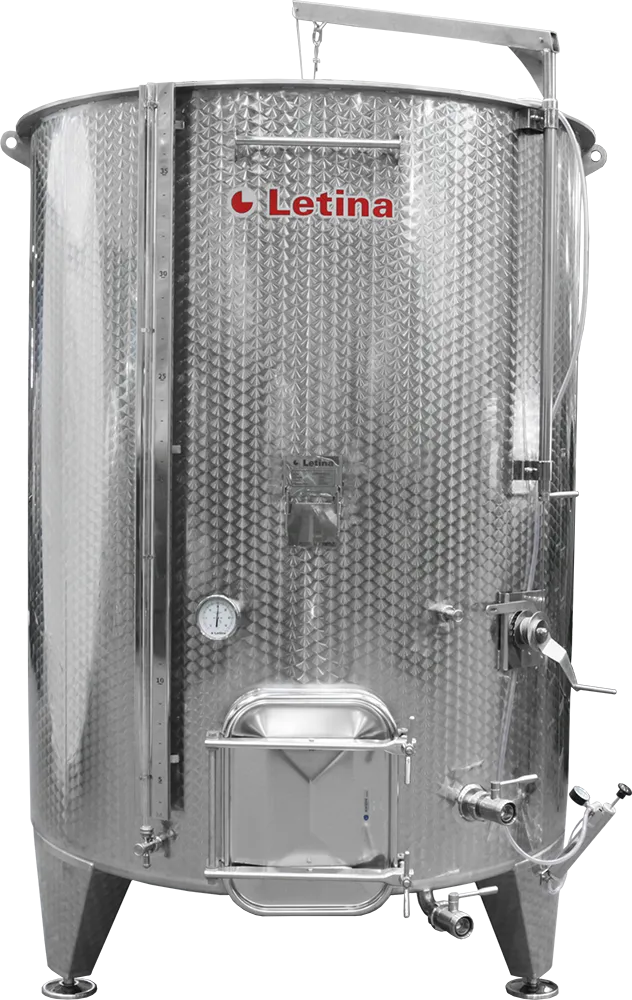

Pump-Over Fermenter with Spoon Bottom

[VIKS] Pump-Over Fermenter - Spoon Bottom

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Pump-Over Fermenter with Pomace Ejection

[VIKM] Pump-Over Fermenter - Pomace Ejection

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tapered Fermenter

[VIKC] Tapered Fermenter

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Punch-Down Fermenter

[VIP] Punch-Down Fermenter

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Punch-Down Fermenter with Spoon Bottom

[VIPS] Punch-Down Fermenter with Spoon Bottom

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Punch-Down Fermenter with Pomace Ejection

[VIPM] Punch-Down Fermenter with Pomace Ejection

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Horizontal Fermenter

[VIN] Horizontal Fermenter

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Charmat Tank

[TC] Charmat Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

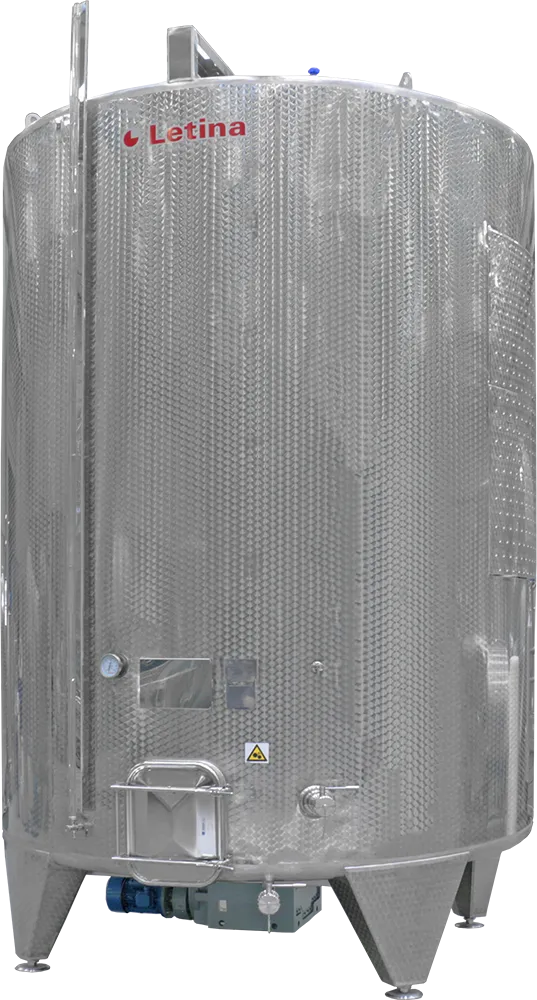

General Use Stainless Steel Storage Tanks

Storage and Fermentation Tank

[Z] Storage and Fermentation Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Square Tank

[KR] Square Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Horizontal Storage Tank

[ZL] Horizontal Storage Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Variable Capacity Tank

[PZP] Variable Capacity Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sloped Bottom Variable Capacity Tank

[PZPK] Sloped Bottom Variable Capacity Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Air Cap Tank

[PZ] Air Cap Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

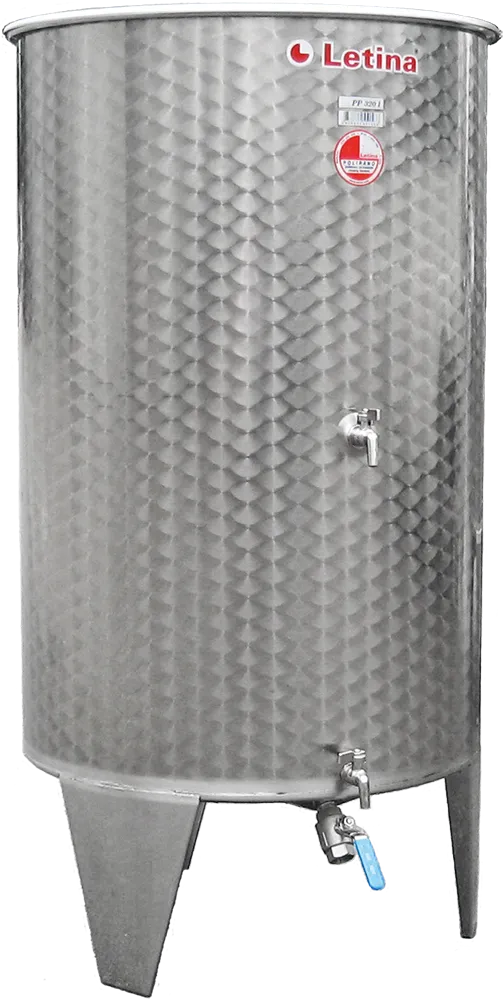

Floating Lid Tank

[PP] Floating Lid Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Pressure Tank

[T] Pressure Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Stainless Steel Winery Equipment

Plate and Frame Filter Press

[VF] Plate and Frame Filter Press

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CIP (Clean-In-Place) Station

[CIP] Clean-In-Place Station

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Biodynamic Dynamizer

[BD] Biodynamic Dynamizer

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Mixing Tank

[M] Mixing Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Grape Juice Separation Tank

[KS] Grape Juice Separation Tank

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Advanced Fermentation Systems & Specialized Vessels

Master the delicate physics of extraction and precise thermal regulation during primary fermentation. Our vessels are engineered to provide winemakers with granular control over phenolic development and yeast kinetics.

Winematic (Horizontal) Fermenters: These specialized rotating fermenters feature internal anchor-type agitators designed for gentle, programmable cap management. This ensures maximum skin-to-juice contact for superior color and tannin extraction without mechanical bruising of the fruit.

Conical & Tapered Fermentation Tanks: Engineered with specific wall angles to optimize natural thermal convection during active fermentation. The tapered geometry facilitates superior yeast sedimentation and harvesting, while making the manual “punch-down” process more effective in boutique gravity-flow wineries.

Pump-over & Punch-down Systems: Fully integrated mechanical maceration tools designed for intensive red wine production. Our automated pump-over systems ensure uniform temperature distribution throughout the must, preventing localized hot spots that can lead to stuck fermentations.

Multi-Zone Cooling Jackets: Utilizing high-efficiency dimpled jackets (laser-welded), our fermenters allow for independent temperature control across different levels of the tank, crucial for managing the heat generated by the pomace cap.

Cellar Space Optimization & Bulk Storage

Maximize your wine storage volume and operational efficiency without the capital expense of expanding your building’s footprint. We specialize in engineering high-density storage solutions for cramped historic cellars and massive industrial sites alike.

KR Series Square Wine Tanks: A proprietary engineering breakthrough that eliminates the “dead space” inherent to cylindrical vessels. By utilizing the full geometry of your facility, these tanks increase cellar storage capacity by up to 25%. They are custom-fabricated to fit flush against corners and walls, creating a seamless, sanitary storage block.

Stackable Wine Tanks (Multi-Chamber): Modular, vertical designs that allow for the storage of multiple distinct batches within the same floor space. Our double-stack or triple-stack configurations are engineered with reinforced structural supports to ensure zero deflection under full load.

Industrial-Scale Wine Silos: For high-volume producers, we manufacture bulk wine storage vessels exceeding 280,000 liters. Every silo is designed using Finite Element Analysis (FEA) to calculate the exact structural requirements for wind loads, seismic activity, and hydrostatic pressure.

Inert Gas Blanketing Systems: Integrated ports for Nitrogen or Argon sparging to prevent oxidation in long-term storage, preserving the freshness of white and rosé wines during the aging process.

Sparkling Wine & Pressure Vessels (Charmat Method)

Master the complexities of secondary fermentation with our high-performance autoclaves and pressure-rated vessels. Specifically engineered for the Charmat (Martinotti) Method, our systems provide the precise atmospheric control required for the production of Prosecco, Sekt, and other sparkling varieties.

TC Series Pressure Tanks: These high-precision, jacketed pressure vessels are dual-certified to ASME U and PED 2014/68/EU standards, ensuring global safety compliance for high-pressure operations.

Isobaric Fermentation: Engineered to maintain constant pressure during the carbonation phase, protecting the delicate mousse and aromatic profile of the wine.

Thermal Management for Stabilization: Equipped with high-surface-area dimpled cooling jackets, our tanks allow for rapid cold stabilization and precise temperature drops to stop fermentation exactly when the desired residual sugar is reached.

Precision Carbonation: Integrated ports for micro-oxygenation and carbonation stones allow for total control over CO2 levels and bubble size, ensuring a consistent final product across every batch.

Integrated Safety Systems: Every vessel is outfitted with certified safety valves, pressure gauges, and reinforced manways designed to handle continuous internal pressures without structural fatigue.