Food & Beverage

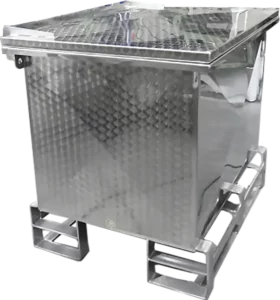

High-Performance Stainless Steel Solutions for the Global Food & Beverage Industry

Precision-engineered processing systems designed for hygiene, efficiency, and the most demanding industrial standards.

In an era where “one-size-fits-all” solutions lead to process inefficiencies, Letina Intech provides bespoke engineering that addresses the technically complex requirements of modern food and beverage production. From individual vessels to integrated process modules, our equipment is designed to maximize throughput while ensuring rigorous hygiene compliance.

We specialize in handling a vast range of product viscosities – from thin juices to thick, challenging pastes like chocolate, ketchup, and peanut butter.

ISO 9001

Quality management system

PED 2014/ 68/EU

Pressure Equipment Directive

EN ISO 3834-2

Quality requirements for fusion welding of metallic materials

ASME U

Boiler and Pressure Vessel Code

VLAREM II

Flemish Regulations on Environmental Permitting

GMP

Compliance for stainless steel surfaces in contact with food

Food and Beverage sectors we operate in

Beverage Production

Bakery

Condiments and Sauces

Confectionery

Dairy Processing

Fats & Oils

Ingredients & Dry Goods

Prepared Foods

Specialized Mixing and Homogenization

The processing of condiments and sauces requires integrated mixing systems that ensure uniform texture and prevent product adhesion to tank walls.

Scraper Agitators: These systems continuously scrape the internal shell to prevent “burn-on” during heating and ensure total product recovery for high-viscosity items like peanut butter.

High-Shear Emulsifiers: We integrate high-speed homogenizers for products requiring stable oil-and-water phases, such as dressings and mayonnaise.

Jacketed Thermal Control: Double-walled designs utilize steam or hot water to maintain precise temperature set-points during the cooking or melting process.

Sector-Specific Solutions

Our engineering team delivers custom solutions across diverse food sub-sectors:

Dairy Processing: Insulated tanks for raw milk storage and cream maturation, featuring ultra-hygienic welds and integrated CIP systems for daily sterilization.

Edible Oils and Fats: Large-volume silos featuring conical bottoms for sediment purging and nitrogen-blanketing ports to prevent oxidative rancidity.

Confectionery: Specialized jacketed chocolate melting tanks with PLC-controlled temperature cycles and gentle agitation for a silky finish.

Prepared Foods: Vertical and horizontal mixers designed for the gentle blending of ingredients without damaging particulates like noodles or vegetables.

Uncompromising Hygiene and Quality Assurance

Every vessel manufactured for the food industry undergoes rigorous verification to ensure it meets international safety standards.

Surface Finish Mastery: Verification that mirror finishes meet required Ra standards (often ≤ 0.4 μm) to prevent bacterial adhesion.

Endoscope Inspections: High-resolution camera inspections of internal weld roots in high-pressure vessels to ensure a defect-free environment.

Material Verification: Every batch of stainless steel (AISI 304 or 316L) is verified via composition analyzers to ensure maximum corrosion resistance.

Global Certifications: Our equipment is manufactured in accordance with ASME U, PED 2014/68/EU, and ISO 9001:2015 standards.